On January 14th, China's largest 66kV direct-mounted Static Var Generator (SVG) equipment (±120Mvar) was successfully commissioned at the Qinchuan 750kV substation in the Gansu Power Grid. This milestone achievement provides valuable practical insights for implementing dynamic and precise reactive power compensation, while improving power efficiency and reducing power loss in ultra-high voltage substations.

66kV Direct-Mounted Static Var Generator (SVG) Equipment

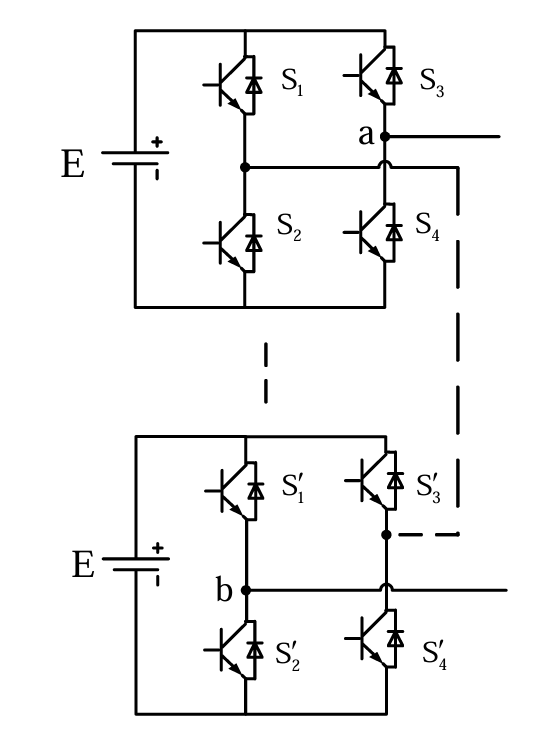

In the Qinchuan 750kV power transmission and transformation project, the installed 66kV ±120Mvar SVG system is primarily designed to dynamically track reactive power fluctuations in the grid, enabling rapid and precise voltage regulation. This advanced equipment significantly enhances grid stability and security while reducing power loss. The system typically utilizes a cascaded H-bridge multilevel topology as follows:

Multi-level Cascaded H-bridge Topology

Each H-bridge module consists of four IGBTs paired with their corresponding anti-parallel diodes, forming a distinctive "H"-shaped circuit structure. As a fully controlled switching device, the IGBT enables precise control over both the amplitude and phase of the output AC voltage through accurate switching operations.

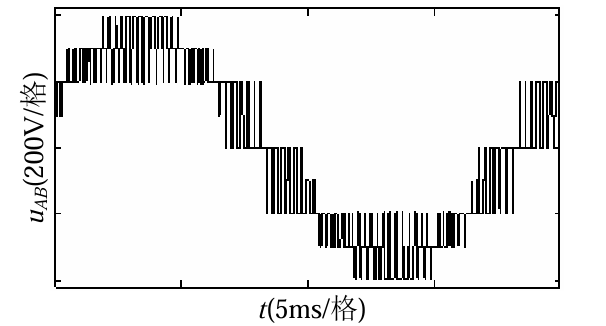

The H-bridge module can generate three specific voltage levels: positive level (+Ud/2, where Ud represents the DC-side capacitor voltage), negative level (-Ud/2), and zero level (0). By cascading multiple H-bridge modules, the system achieves a expanded range of voltage levels, significantly enhancing the accuracy of the output voltage waveform.

Output Voltage Waveform

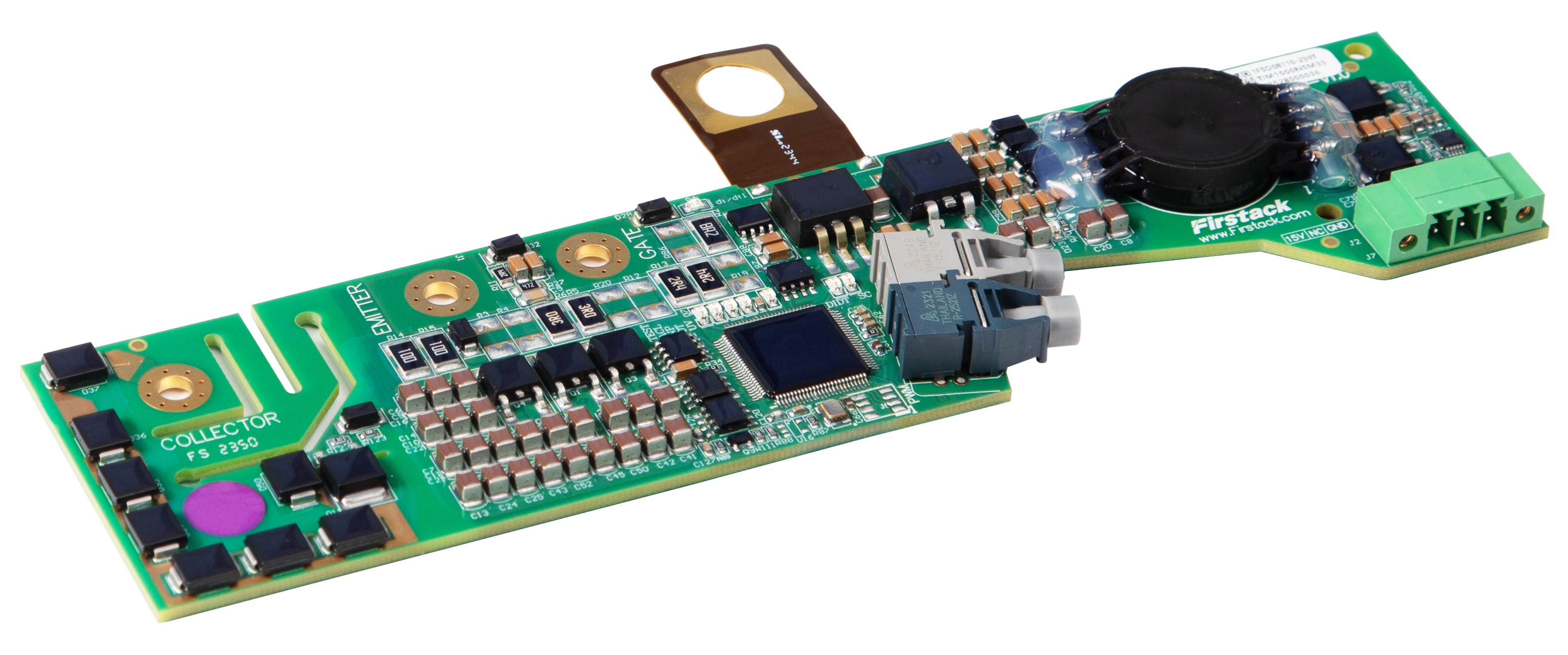

As a key enabling technology, 1FSD08110, Firstack Digital Plug-and-Play Driver for IGBT, features exceptional switching performance and comprehensive protection, which are essential for achieving precise and reliable reactive power regulation in modern SVG systems.

Firstack 1FSD08110 GDU

For direct-mounted SVG systems operating in high-voltage environments, the DC bus voltage can experience significant fluctuations under extreme grid conditions, with peak values potentially surpassing the rated voltage by 30% to 40% (e.g., Vdc_nom=1800V, Vdc_max=2400V). These demanding conditions pose considerable challenges to IGBT reliability, particularly in terms of overvoltage failure. 1FSD08110 addresses these risks through two key technological advancements.

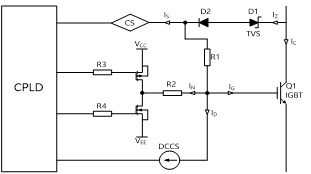

Advanced Digital-Controlled Dynamic Active Clamping Technology

1. Advanced Digital-Controlled Dynamic Active Clamping Technology

Under abnormal operating conditions, such as system overload or load-side short-circuit events, IGBTs experience significantly higher turn-off currents. Active clamping technology plays a critical role in mitigating turn-off overvoltage and ensuring reliable device operation.

Firstack has developed an proprietary solution to optimize clamping efficiency and circuit reliability: Advanced Digital-Controlled Dynamic Active Clamping Technology. This technology integrates a digitally controlled current source into the gate circuit. When the system detects that the TVS current (IZ) exceeds a predefined threshold, it simultaneously deactivates the N-channel transistor and activates the digitally controlled current source. This creates the relationship IZ = IG + ID, allowing precise current regulation through the digitally controlled source. As a result, the TVS maintains a controlled breakdown state at minimal current levels during the turn-off transient.

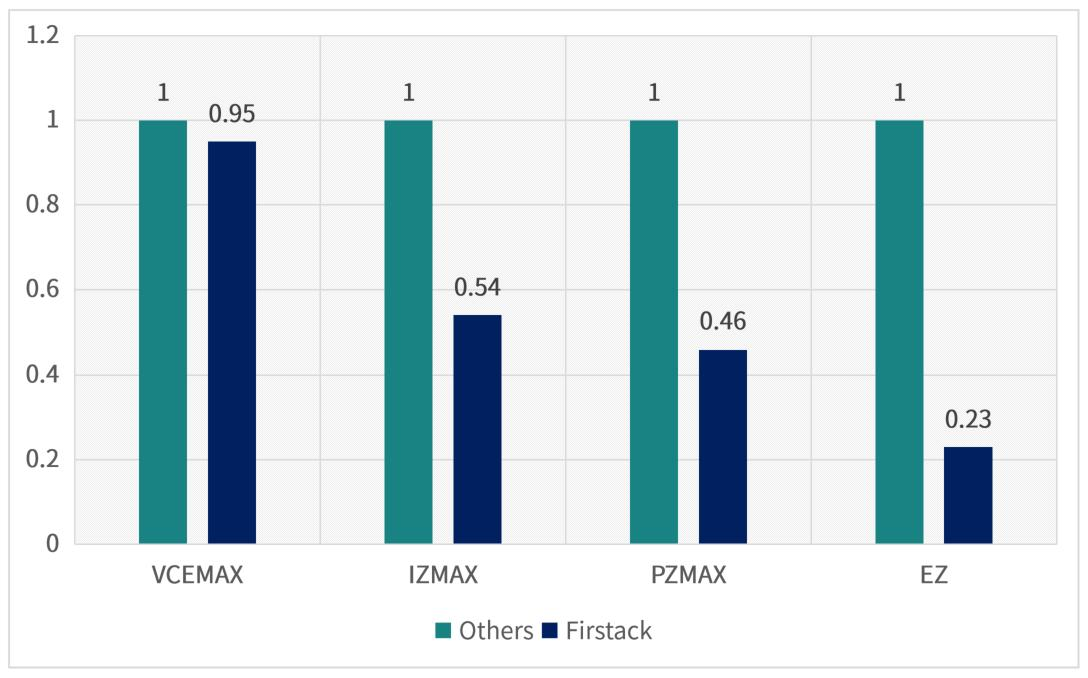

Compared to conventional active clamping solutions, this technology delivers superior performance in clamping efficiency and TVS power management. Experimental results show a remarkable 75% reduction in TVS power dissipation compared to competing products (as illustrated in the accompanying figure). Additionally, the power dissipation remains highly stable across varying turn-off current levels, significantly enhancing both the longevity and extreme-condition reliability of the active clamping circuitry.

Comparison of Key Parameters

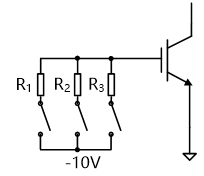

2.Multi-Level Turn-Off

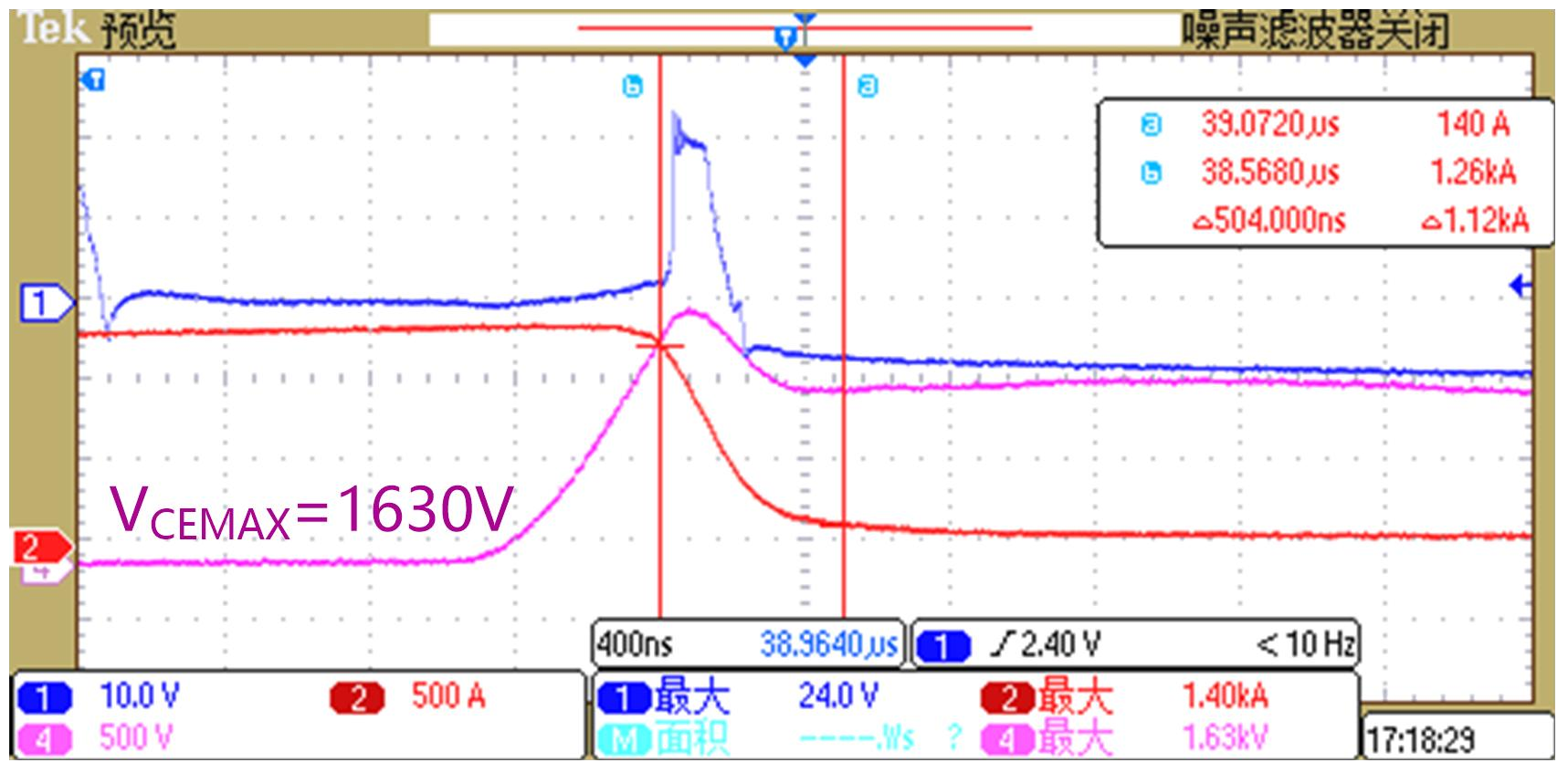

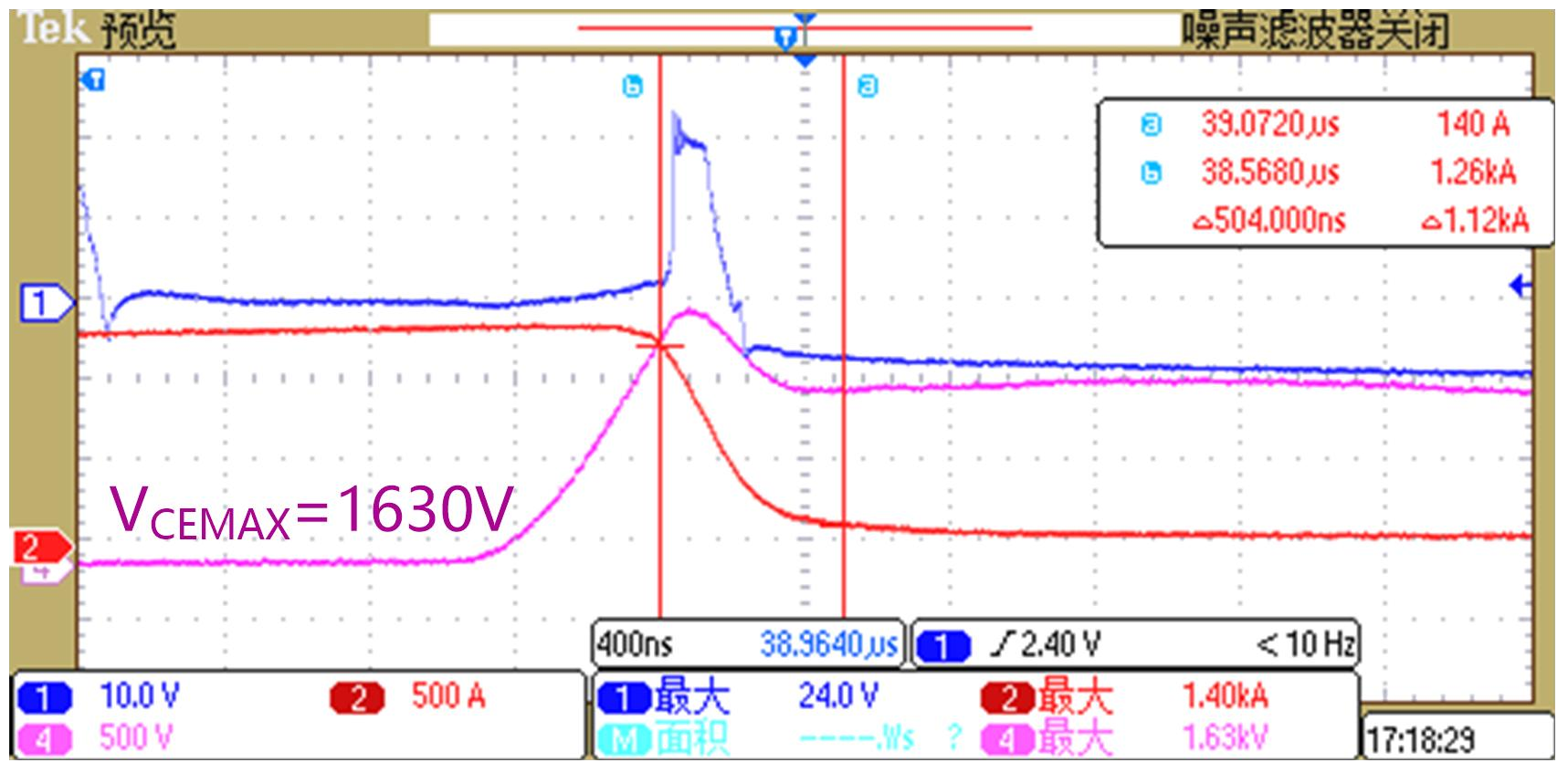

Firstack's digital driver employs an advanced multi-level turn-off strategy by dynamically adjusting gate resistance values during the IGBT turn-off process. This approach significantly reduces voltage overshoot during switching transitions. Experimental results using the FF1000R17IE4 module demonstrate the effectiveness of this technology: the maximum collector-emitter voltage (VCE_MAX) decreases from 1630V (without multi-level turn-off) to 1330V (with multi-level turn-off) under the same operating conditions, achieving a notable 20% reduction in voltage peak.

Multi-Level Turn-Off Technology

Output Waveform Without Multi-Level Turn-Off

Output Waveform With Multi-Level Turn-Off

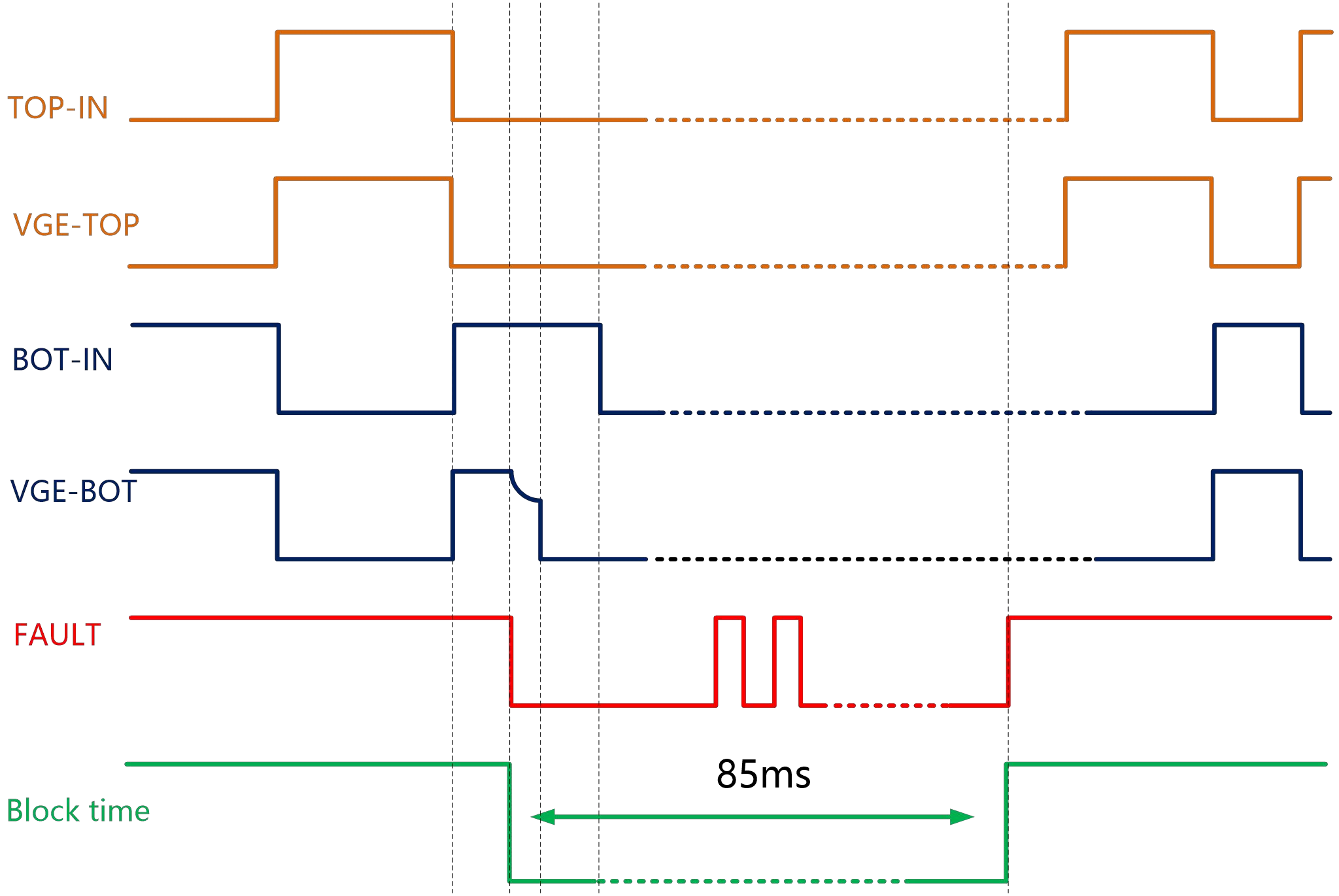

To improve fault diagnosis capabilities in IGBT systems, Firstack has developed an intelligent digital fault communication system with advanced fault localization features.

This system outperforms traditional imported drive solutions by utilizing encoded serial communication for fault data transmission. As shown in the accompanying diagram, the technology provides detailed fault diagnostics to the supervisory system, including fault classification and timing information. This capability enables rapid system-level fault identification and contributes to the digital transformation of critical SVG components in power grid applications through intelligent management solutions.

Intelligent Fault Management